Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

Views: 2652 Author: Site Editor Publish Time: 2024-08-16 Origin: Site

The NJP Series Fully Automatic Hard Capsule Filling Machine is an integrated mechanical-electrical-pneumatic system. Powered by a main motor, it drives the indexing box and cam-linkage mechanism to coordinate operations across multiple stations. These stations perform capsule separation, material filling, defect rejection, capsule closure, product ejection, and module cleaning functions. Featuring a compact structure, advanced automation, high machine adaptability, rapid production speed, high filling accuracy, material recovery efficiency, fast mold replacement capability, and low operational noise, this equipment delivers exceptional performance in industrial applications.

The filling accuracy serves as a critical performance indicator in capsule filling machine production. Our company's capsule filling machines employ a plugging-type quantitative method, where the filling volume is determined by the diameter and thickness of the metering disc holes, which are closely related to the bulk density of the material being filled. Notably, this precision is influenced not only by the machinery itself but also by the production environment and inherent characteristics of the materials being processed.

1. Production environment of filling machine: The working environment of filling machine is temperature: 21+3℃, humidity: 40%-60%. However, for materials with high sugar and fat content, the temperature should be reduced as far as possible; for materials that are easy to absorb moisture, the humidity should be reduced as far as possible. Avoid material sticking to the filling machine, resulting in excessive variation in filling volume.

2. Material Characteristics: The ideal material should have a particle size of 80-100 mesh, uniform particle size, consistent density, no stratification, moisture content below 3%, moderate flowability, non-stick to filling rod, no static electricity generation, and easy to compress into a pill column. Where pharmaceutical processes permit, these standards should be approached as closely as possible to enhance filling accuracy.

III. Influence and adjustment of filling machine structure:

1. Influence of mold finish

Ensure all components of the filling machine are in good condition without defects. Focus on inspecting the metering disc bore and filling rod end face, requiring no dents, foreign objects, scratches, and maintaining high surface finish. Improving the surface finish of these components can help reduce adhesive erosion to some extent, thereby enhancing filling accuracy.

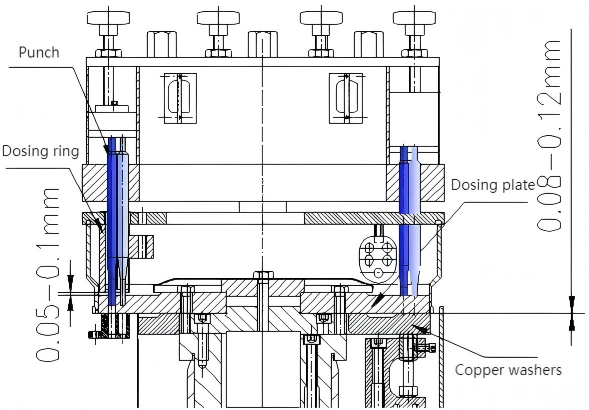

2. Influence of gap between copper ring, isolation block and metering plate

The copper ring serves to support materials within the measuring disk's borehole. A smaller gap between the copper ring and measuring disk reduces powder leakage, which helps improve filling accuracy. Typically, the gap is adjusted to 0.08-0.12mm. For materials with high viscosity and low melting points, prolonged operation may increase resistance in the measuring disk, potentially causing jamming or seizure. In such cases, a slightly larger gap is preferable, but the maximum gap should not exceed 0.2mm. Additionally, ensure the contact surface between the measuring disk and copper ring maintains optimal smoothness.

The isolation block in the filling ring plays a role in separating the filled material and the material to be filled. If the material to be filled is mixed into the filled material, it will affect the measurement accuracy. Under normal circumstances, the gap between the isolation block and the metering disk is 0.05-0.1mm, the smaller the better, and it is not necessary to rub against the metering disk.

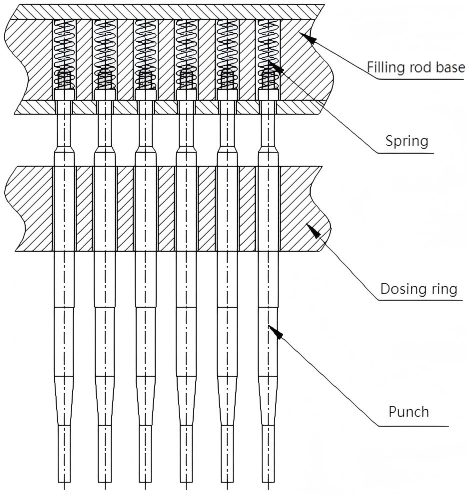

3. Influence of filling rod on material pressure

The pressure of the filling rod on the material in each group of clamps should be consistent. When pressurized, the jumping state of the filling rod should be no obvious difference. If there is obvious inconsistency, the material will be subjected to different pressure, which will affect the filling accuracy.

It is necessary to check whether there are materials, foreign objects and burrs on the filling rod seat hole and the filling rod, and clean and remove the burrs. A single filling rod should fall freely into the filling rod seat hole without resistance.

Check the spring force consistency in the holder body: Remove the holder body and keep it horizontal. Observe whether the filling rod end hangs uniformly. Shake the holder body to check the swinging amplitude of the filling rod. If significant differences are found, replace the spring.

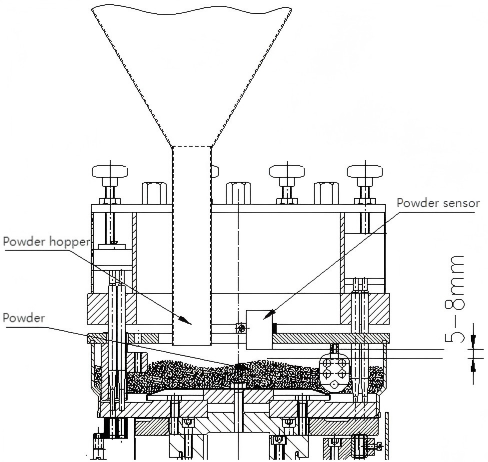

4. Influence of material height in the powder ring

The change of material height and the unevenness of the material surface in the powder ring will cause the material in the metering disc hole to be inconsistent every time the compaction pressure is applied, which will affect the filling accuracy.

Adjust the sensor's detection range to maintain a 5-8mm distance between the sensor and material surface, with indicator light flickering accordingly. On the touchscreen, set the feeding delay time (typically 1-3 seconds) to ensure minimal yet frequent feeding. This maintains stable material levels within the powder ring, keeping fluctuations within a narrow range.

When material flow exhibits poor uniformity with uneven distribution and surface irregularities within the powder containment ring, implementing these solutions can effectively improve surface flatness: 1) Adjusting the sensor height to optimize material accumulation; 2) Increasing machine speed within permissible parameters; 3) Installing a material distribution disc within the containment ring. These measures collectively enhance operational efficiency while maintaining operational stability.

5. Influence of material on the column state of compressed medicine

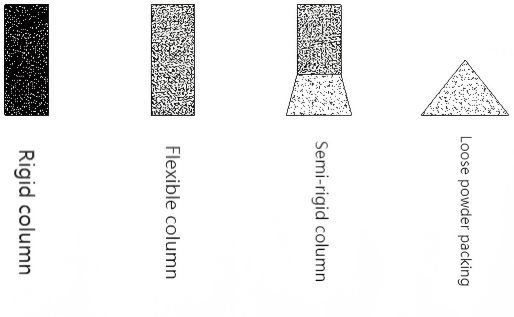

Due to the different properties of the material, the state of the medicine column formed under the action of the measuring plate and filling rod is also different, which can be roughly divided into hard column, soft column, half column and loose sand.

Hard columnar: the particle weight is stable, the weight is close to the maximum value, the weight range is small, the filling rod has obvious jumping during compaction, the machine load is large, and the corresponding parts wear out.

Soft column: the grain weight is stable, the weight can be adjusted over a large range, and the machine load is small.

Semi-columnar: The drug column is unstable in character, with loose and broken parts, and there may be a phenomenon that the material is not easy to enter the capsule and the filling weight becomes lighter. Under the condition of allowable net weight, the measuring disk and filling rod of a smaller size can be replaced for this kind of material to improve the filling accuracy of this kind of material.

Loose sand: high particle hardness and completely no column, more powder leakage, large difference in filling. Our company's copper ring with shield and anti-fall powder device can prevent material leakage in advance and improve the difference in filling of such materials.

6. Adhesion phenomenon

The sticking phenomenon commonly occurs with full-powder materials characterized by high mesh sizes, moisture absorption tendencies, or higher sugar/fat content. These materials require strict temperature and humidity control in storage environments. If the issue persists, inspect the metering disk holes and filling rod surfaces for surface imperfections. Any scratches or burrs should be promptly removed and polished. Alternatively, adjusting the cam and indexing box angles can create friction between the lower module and the filling rod's end face, effectively retaining material within the module's bore.

7. Find the pattern

Most of the filling machines in our company have a separate holder body and a double discharge trough structure, which can weigh the weight of capsules in front and back rows respectively, or the weight of capsules on both sides of the same row. To find out whether there is a regularity, the separate holder body can be adjusted, or corresponding treatment can be done according to the regularity of deviation.

IV. Under normal circumstances, the loading accuracy has the following rules:

1. The hole with fine diameter is more stable than the hole with coarse diameter;

2. The thin plate is more stable than the thick plate;

3. The material with high bulk density is more stable than that with low bulk density;

4. The stable material surface of the powder ring is higher than that of the lower material surface;

5. The inner material surface of the powder ring is stable than the uneven one;

6. The material surface with small fluctuation is more stable than the material surface with large fluctuation.

In short, the filling accuracy of the capsule filling machine is not determined by a single factor, but by the equipment state, environmental factors and material properties. The combination of the three directly affects the product quality.

content is empty!