Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

Views: 3265 Author: Site Editor Publish Time: 2024-07-01 Origin: Site

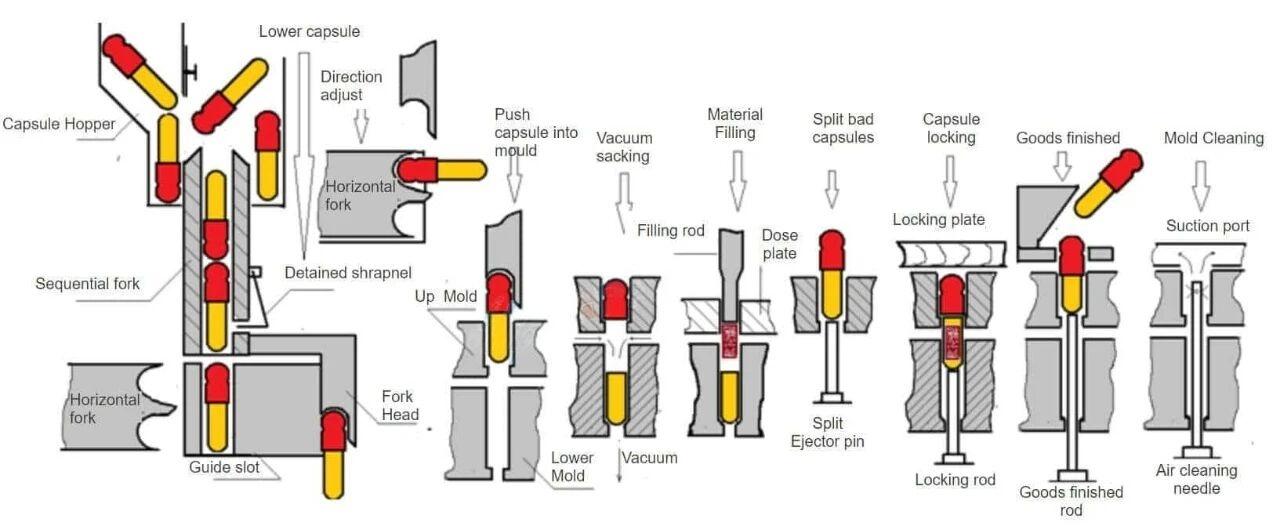

The automatic capsule filling machine is composed of multiple parts, which together constitute a complete automation system. In general, these parts can be divided into mechanical, electrical and pneumatic categories, and constitute fixed parts or moving parts respectively.

Capsule feed hoppers, typically made of stainless steel, store empty capsules awaiting filling and are designed in cubic, cylindrical, or conical configurations. These hoppers are equipped with level sensors that monitor capsule quantities. When the number of capsules falls below or exceeds preset thresholds, the system automatically replenishes the hopper or halts operation. Additionally, some hoppers incorporate gate valves to regulate capsule intake at filling stations.

The capsule feeding device is typically equipped with a continuously rotating metering wheel that only allows intact capsules to enter the main hopper. Capsules can be conveyed to the hopper via a lifting belt or vibration system. The feeding device is usually positioned above the equipment and connected to the main hopper through vacuum conveying technology.

3. Powder hopper (with screw feeding device)

Powder hoppers are designed to store materials awaiting filling and deliver them to filling mechanisms via screw conveyor systems. These hoppers may incorporate level sensors for detecting powder levels and controlling replenishment. Some models feature automatic blending functions to ensure uniformity of the powder. All powder hoppers are manufactured from stainless steel.

The dosing filling device is designed to accurately measure and deliver powder into molds. Its integrated level sensor automatically controls powder supply. During the filling process, the powder is first stored in a metering tray before being injected into the mold cavity below. Some units feature a dual-dose filling system to enhance efficiency.

The rotary table features a fully enclosed design that prevents dust contamination of moving parts, meeting cGMP standards. Capsules are precisely positioned and conveyed within the rotating table through continuous motion during processing, ensuring accurate positioning and filling before sealing. The rotary table's design directly impacts both the ease of cleaning validation and adaptability to different filling formulations.

The motion of an automatic capsule filling machine relies on a mechanical transmission system, which can be driven by linear, rotational, or reciprocating motions—all powered by motors. In modern equipment, critical components such as drive gears and transmission mechanisms are typically housed in fully enclosed structures to prevent dust ingress. The entire system is controlled by a PLC (Programmable Logic Controller) to ensure precision and consistency throughout the powder filling process.

7. Lubrication systems

The lubrication system automatically applies lubricant to the dosing plate, powder press, and other moving parts, reducing friction, extending equipment lifespan, and ensuring smooth filling. Modern equipment features precision oil filtration systems that enable centralized lubrication with food-grade lubricants.

The vacuum system plays multiple roles in the equipment, including:

Connect the capsule feeding part with the capsule hopper;

Achieve capsule separation (lid and shell);

Powder vacuum transportation;

Cleaning system (some equipment is automatically cleaned in each cycle);

Vacuum extract material for filling.

The system is the core auxiliary module to achieve efficient and automated operation.

The safety door is connected with the protection switch. Once the operator opens the door, the equipment will stop automatically to prevent personnel from touching high-speed moving or live parts and ensure operation safety.

The fully automatic capsule filling machine is typically equipped with a Siemens PLC and a human-machine interface (HMI) touchscreen, ensuring intuitive and convenient operation. The control system features microcurrent protection, motor overload protection, emergency stop buttons, vacuum pressure monitoring, and intelligent mold control. Operators can adjust parameters and monitor the system through the HMI. With its high degree of automation, the system significantly reduces manual intervention and operational costs.

The capsule automatic feeding device can be started or stopped automatically according to the material level, effectively meeting the demand for high output. Some equipment is equipped with a double material tray structure, which is suitable for medium and large-scale production, reducing labor costs and improving production efficiency.

The device is usually integrated with the vacuum system to automatically convey the powder to the powder hopper, and can automatically start and stop the feeding according to the setting, to prevent powder waste or product unqualified due to broken feeding. It is suitable for continuous and large-scale production.

The capsule polishing machine can be directly connected to the discharge end of the filling equipment to clean and polish the capsules. It simultaneously removes abnormal light/heavy or empty capsules through weight detection, sorting, and metal detection, without damaging the capsule printing. Compared with traditional polishing methods, this equipment is more efficient and reliable in improving capsule quality.

Although the automatic capsule filling machine is composed of hundreds of components inside, it is important to master these 13 key components and their functions for equipment selection, operation and maintenance.

content is empty!