Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

CGN208-D

Innov

CGN208-D Pharmaceutical Powder Pellet Semi Auto Capsule Filling Machine

Machine Application

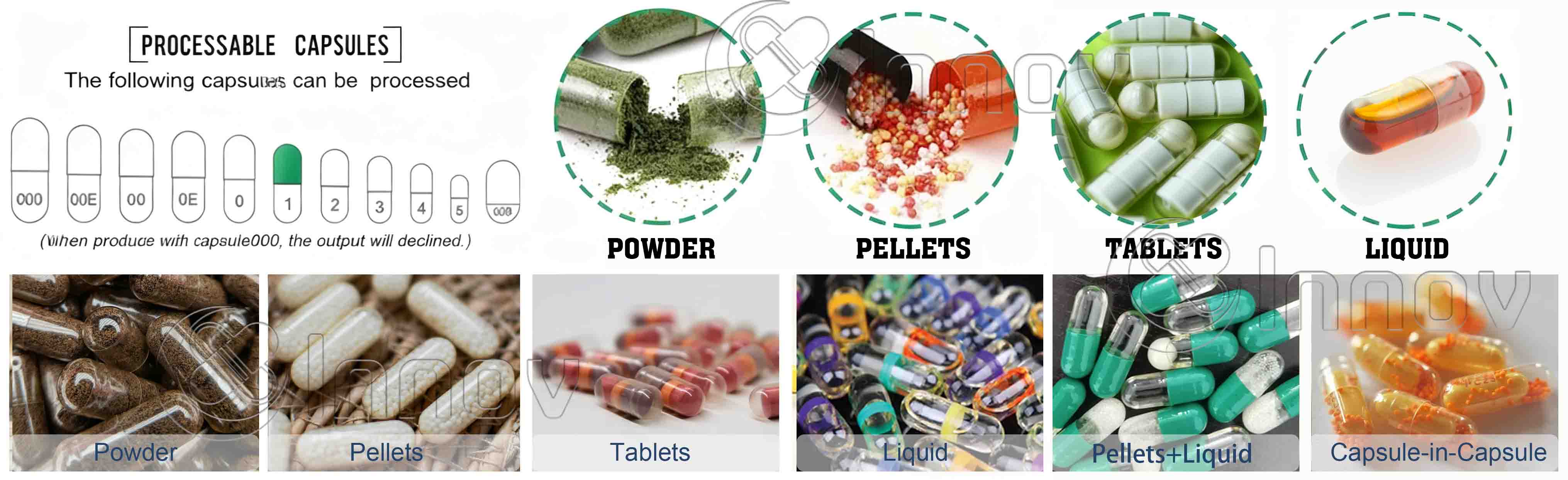

Equipped with button panel control, all the operation are very easy and simple, it can be adopted to fill both the chemical and herbal powder. The machine body and working table adopt stainless steel, it is easy to connect to the vacuum feeder. The machine confirms to the GMP sanitary requirement of pharmaceutical, nutrition, supplement and herbal medicine industries, suitable for filling powder, pellet, liquid, tablet and small capsules etc products.

Machine Features

1. The new vertical(D) capsule filling machine is a performance-improvement product designed by our company to address the insufficient performance of the existing horizontal capsule filling machines on the market.

2. The new capsule sowing device adopts a more user-friendly independent support and power separation design, which can operate more stably and with lower noise (patented)

3. The linear track type bag control switch is more convenient and precise to adjust the opening position of the bag control frame. (patent)

4. The front panel of the small capsule hopper can be opened independently, making cleaning the capsules more convenient and faster. (patent)

5. Both large and small capsule hoppers adopt quick positioning devices, which can be quickly positioned, disassembled and assembled without tools. (patent)

6. The capsule disk uses linkage operation to avoid the disadvantages of continuous acceleration and deceleration compared with the original gap operation, and can achieve high-speed and stable operation. (patent)

7. The capsule disk rotation design easily achieves smooth capsule separation of separated capsules.

8. The capsule tray display rack adopts a simple storage design, which can be easily expanded and stored, making it more user-friendly. (patent)

9. The lower support filling station realizes the short lever to support the overall filling station, making the filling more stable and accurate.

10. The feeding screw power adopts a multi-stage positioning design, making the filling more stable and quiet. (patent)

11. The new safety horizontal locking device overcomes the disadvantages of the original model’s cylinder and air pipe adjustment device being exposed, and the safety index is greatly improved. (patent)

12. The powder sifting type bag discharging mechanism can realize rapid overall disassembly and positioning installation within half a minute, realizing convenient and thorough cleaning without dead corners. (patent)

13. The body and work surface are made of 304 stainless steel to prevent corrosion and oxidation.

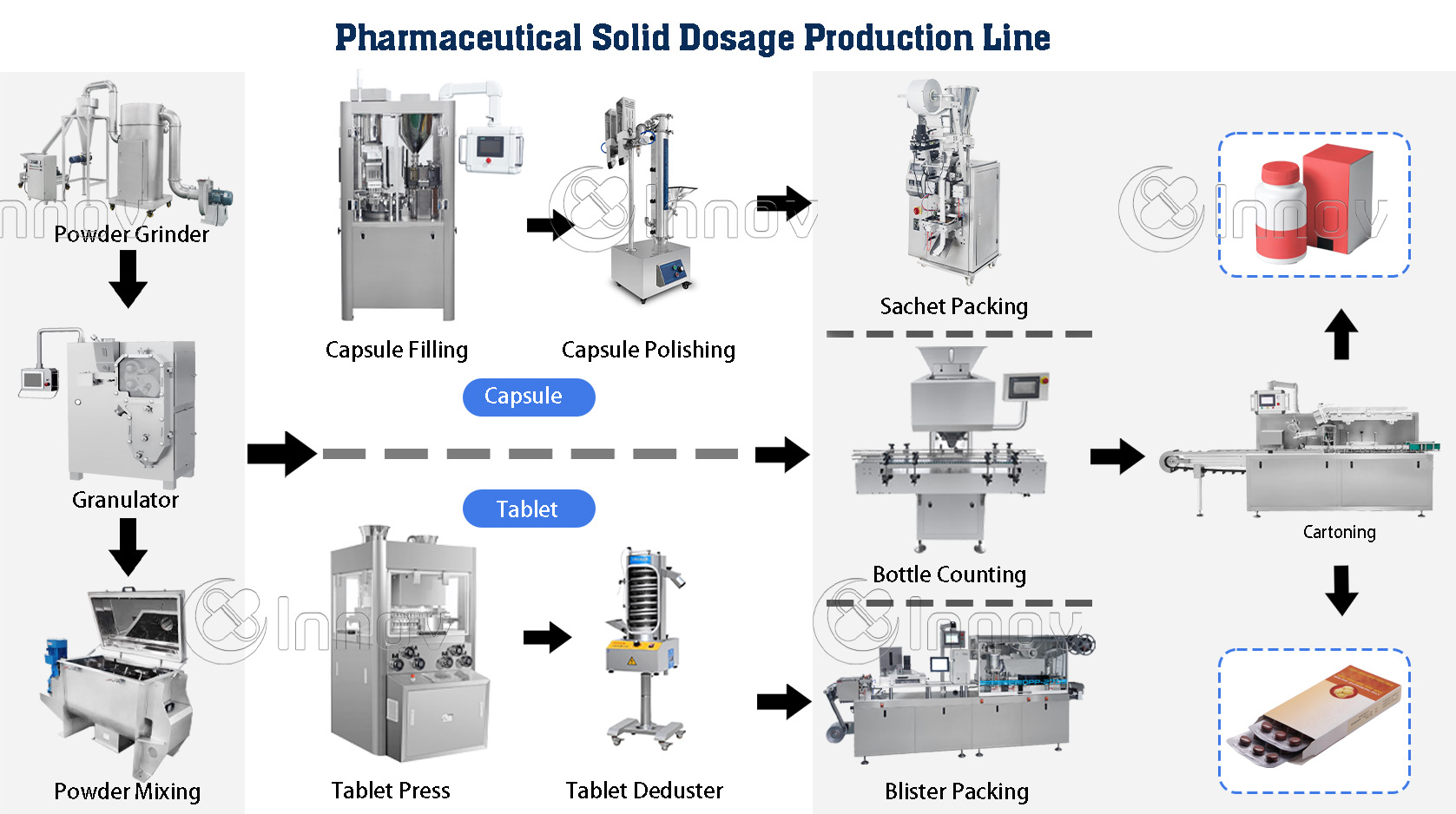

Working Process

CGN208-D semi-automatic capsule filling machine has separated empty capsule feeding station, powder feeding station and capsule closing station. The machine use three inverters to control the speed of capsule feeding turret, powder feeding turret and the powder feeding auger, and adopts the new type capsule feeding structure.

Technical Parameters

Item NO. | Description | Semi Auto Capsule Filling Machine Models | ||

CGN208-D | CGN208-D1 | CGN208-S | ||

1 | Mould changing time | 5--10mins | ||

2 | Production capacity |

25000-30000 pcs/hour(depend on capsule size)

| 25000-40000 pcs/hour(depend on capsule size)

| |

3 | Suitable capsule size | 00#,、0L#、0#、1#、2#、3#、4#、5#、 (000#、00L, customized) | ||

4 | Filling type | Pellet, powder without moisture, granules | ||

5 | Total Power | 4.0kw | ||

6 | Compressed air | 0.03m3/min 0.7Mpa | ||

7 | Vacuum pump | Pumping rate 63m3/h | ||

8 | Overall machine dimension (L*W*H) | 1.63X0.7X1720 m | ||

9 | Overall package dimension (L*W*H) | 1.72×0.83×1.76 m | ||

11 | Net weight | 400 kg | 450kg | |

12 | Gross weight | 520 kg | 550kg | |