Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DPH-280H

Innov

Our advantages

1-Our machine is equipped with servo traction.

2-Our machine is equipped with 1 set of heat sealing-blanking station safety cover as standard.

3-The structure of this machine is more reasonable. The working platform is a balcony type with no dead corners, making it easier to clean and maintain.

4-Optional PVC and PTP fragment shutdown and automatic alarm functions.

5-Optional safety cover opens, automatic alarm function.

6-The four-station adjustment synchronous belt with digital display,shows the forming, heat sealing, creasing, and punching stations, making the operation more convenient.

7-The quick-connect mold makes it easy and fast to replace the mold, and can be completed by one person in a short time; the forming mechanism, heat sealing mechanism and punching mechanism of different molds have a common positioning reference, and the parts that need to be adjusted are all indicated by scales.

8-The cam box and box seat at the molding, heat sealing, indentation, and punching stations are all made of cast steel and will never be deformed or damaged

9-The main workstations such as forming, heat sealing, creasing, and punching are the reference planes of the main frame on both sides, making its center of gravity more stable and durable; it occupies a small area, large space, and is more convenient to clean

10-Electricity, gas and water are independent, the structure is simple ,safer and easy to maintain and operate.

11-PVC connection platform can be added as optional.

12- The hopper for capsule and tablet will be made to be round in the future( photos will be provided later )

13-The appearance of the whole machine is decent and more advanced.

Sample photo

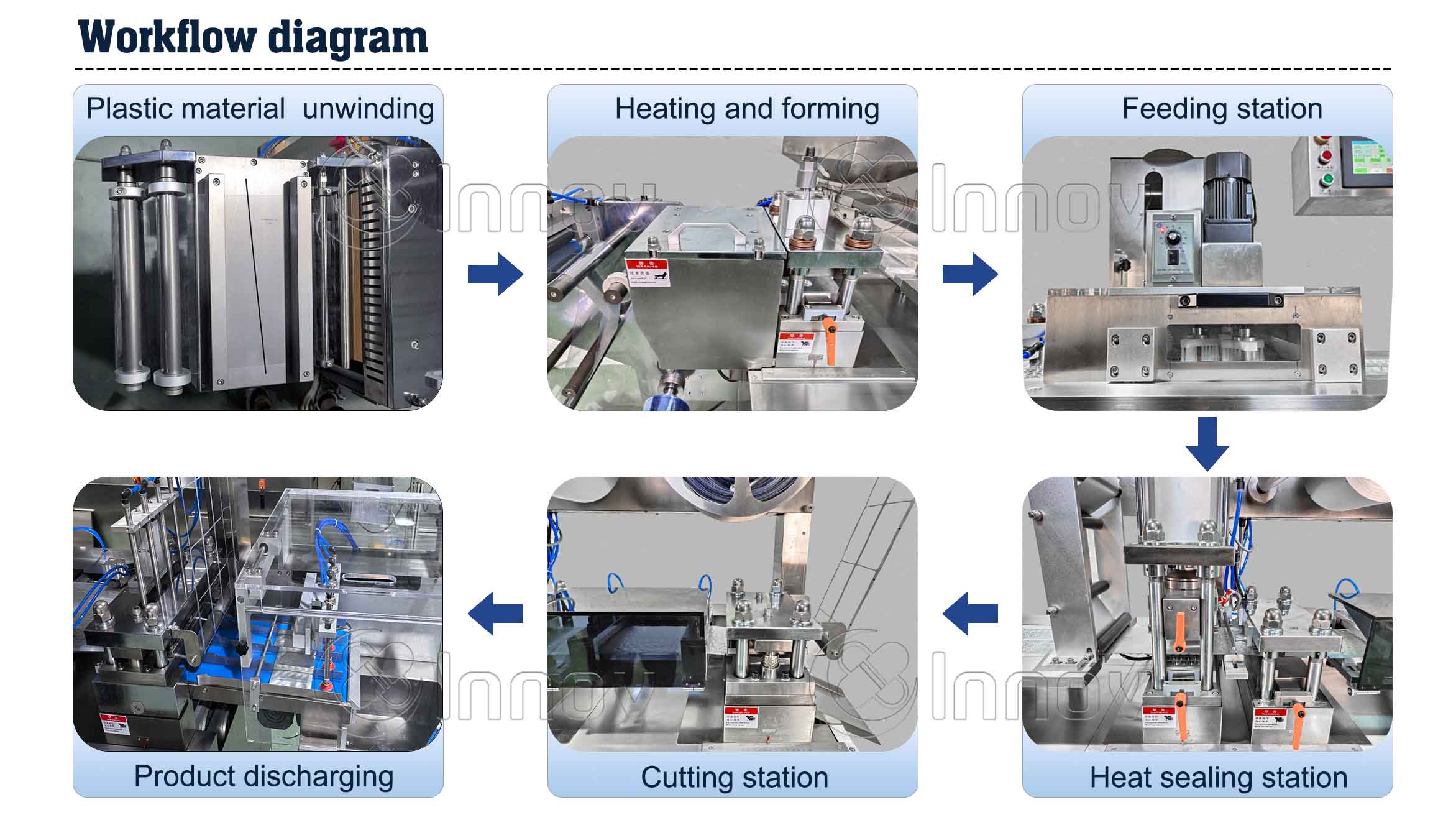

Main working station :

(1) Molding station(quick-connect model)

(2)Heat sealing station(quick-connect model)

(3)Perforation station

(4)Servo traction position

(5)Punching station

(6)Servo manipulator blister rejection and separation conveyor(optional device for connection with flow packing machine or cartoning machine)

(7)Pneumatic control system and electrical box behind the equipment

(8)Eye mark tracking (optional)

(9)Special feeder for Aluminum-Aluminum(optional)

(10)Camera detection and rejection device (optional)

Performance characteristics

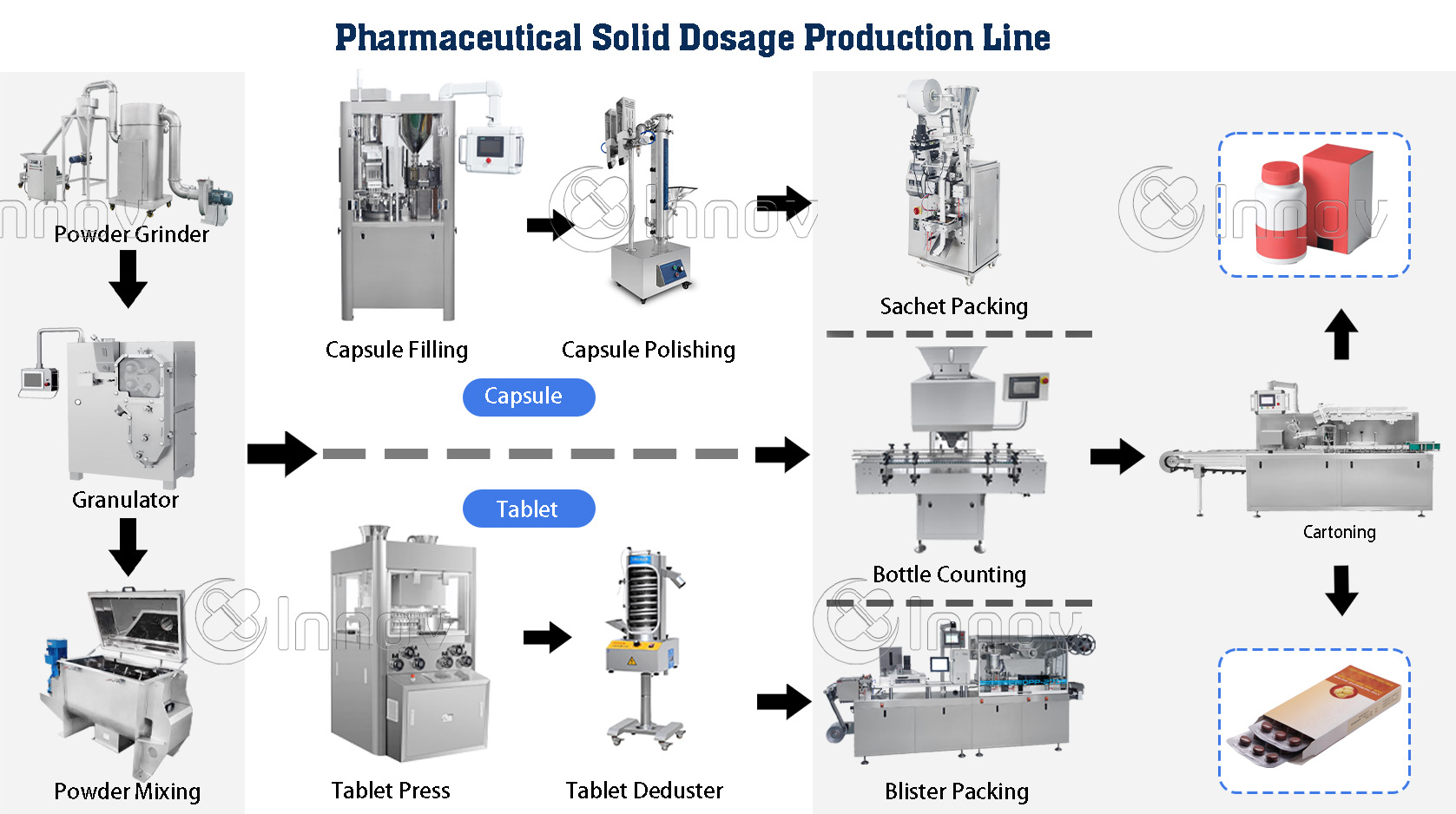

The machine integrates light, mechanism, electricity and compressed air , and is controlled by PC buttons or PLC programmable control. It is suitable for aluminum-plastic, paper-aluminum, aluminum-aluminum and other packaging in the pharmaceutical, food, electronics, medical equipment, hardware and other industries.

(1)This machine can realize two packaging methods: Aluminum foil-plastic and Aluminum-Aluminum.One machine can be used for both products.

(2)This machine is a lengthened type and adopts split combination, making it easy to enter the elevator and purification workshop.

(3)This machine is an elongated type, and the length of the feeding station from molding to heat sealing is 1.4m. It is convenient for customers to choose a special feeder or camera detection system to ensure the filling rate of the feed and the yield of the product.

(4)The mold is equipped with a central positioning groove, which is easy and fast to replace; aluminum alloy rails matching the mold can also be selected for easier adjustment.

(5)This machine has an enlarged cam, which allows the maximum depth of the blister to reach 16mm, which meets the special requirements of honey pills, medical equipment, food and other industries.

(6)The mechanical transmission and electrical transmission of this machine are separated, and the stainless steel outer cover is changed to an open-door type to facilitate operation, repair and maintenance.(7)The whole machine adopts an integrated arch plane frame, which makes the machine more accurate, strong and durable, and avoids cross-contamination; all parts that come into contact with the drug are carefully made of high-quality 316 stainless steel and high-quality aluminum alloy non-toxic materials, fully complying with GMP standards.

Technical parameters

Name | Specification |

Punch frequency | 40~180 pcs/min(Alu-PVC) 20~120 plates/min(Alu-Alu) |

Production capacity | 1.8~23.6 ten thousand pills/hour(Alu-PVC) |

Max. forming area | 130×250mm |

Max. forming depth | Standard:14mm Customized: 26mm(Aluminum foil-plastic),with additional cost 18mm(Aluminum-Aluminum),with additional cost |

Stroke range | Standard:40~130mm Customized:40~160mm with additional cost |

Standard plate size | 80×57mm |

PVC and PTP width and thickness | PVC:270×0.15~0.45mm PTP:270×0.02~0.03mm Duralumin:260 |

Power supply | 380V 50HZ,Main motor 1.5KW,Heating 4.5KW |

Air consumption | ≥0.2m3/min |

Water required for cooling | Tap water or circulating water consumption 60L/H |

Overall dimension | 3600×720×1650mm |

Overall weight | 1700kg |