Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

The Dry Granulator (Roll Compaction System) transforms powders into uniform granules without liquid binders, ideal for heat-sensitive materials in pharmaceuticals, food, and chemicals. Using precision rollers, it compresses powders into dense flakes, milled into adjustable-size granules. Features GMP-compliant stainless-steel design, continuous closed-loop processing, and energy-efficient operation to enhance flowability, reduce waste. Perfect for tablet formulations and additive production.

Features:

1. Dry powder is directly granulated without any binder;

2. The material is mechanically extruded and formed without destroying the chemical properties of the material or reducing the effective content of the product;

3. The pressing wheels are arranged up and down to eliminate the influence of gravity on the material and ensure the uniformity of the material before tableting;

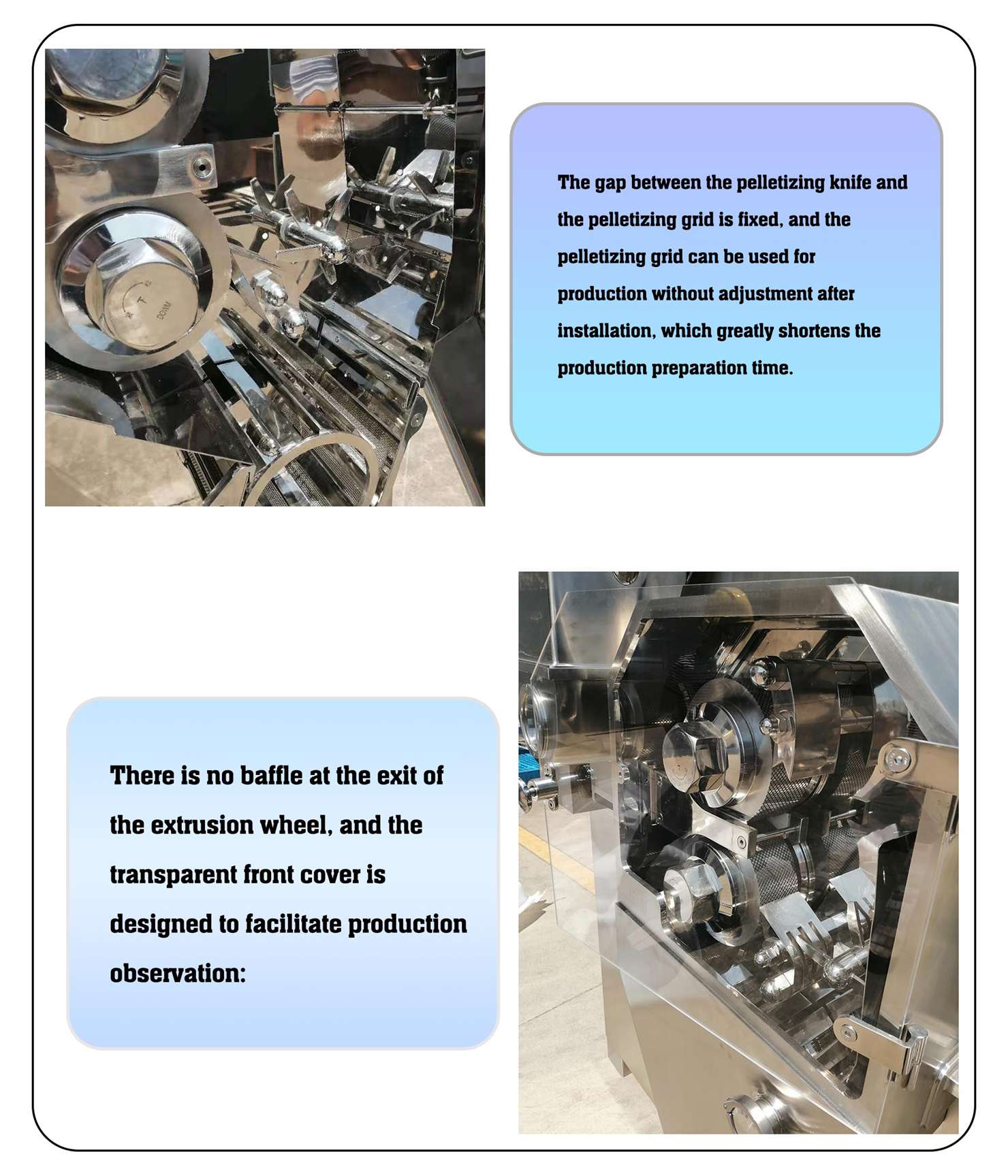

4. The gap between the pressing wheels is adjustable to ensure consistent tableting density and uniform granulation;

5. Low energy consumption and small footprint;

6. High granulation rate and high production efficiency;

7. Equipped with a hydraulic system, the hardness and density of the particles are adjustable;

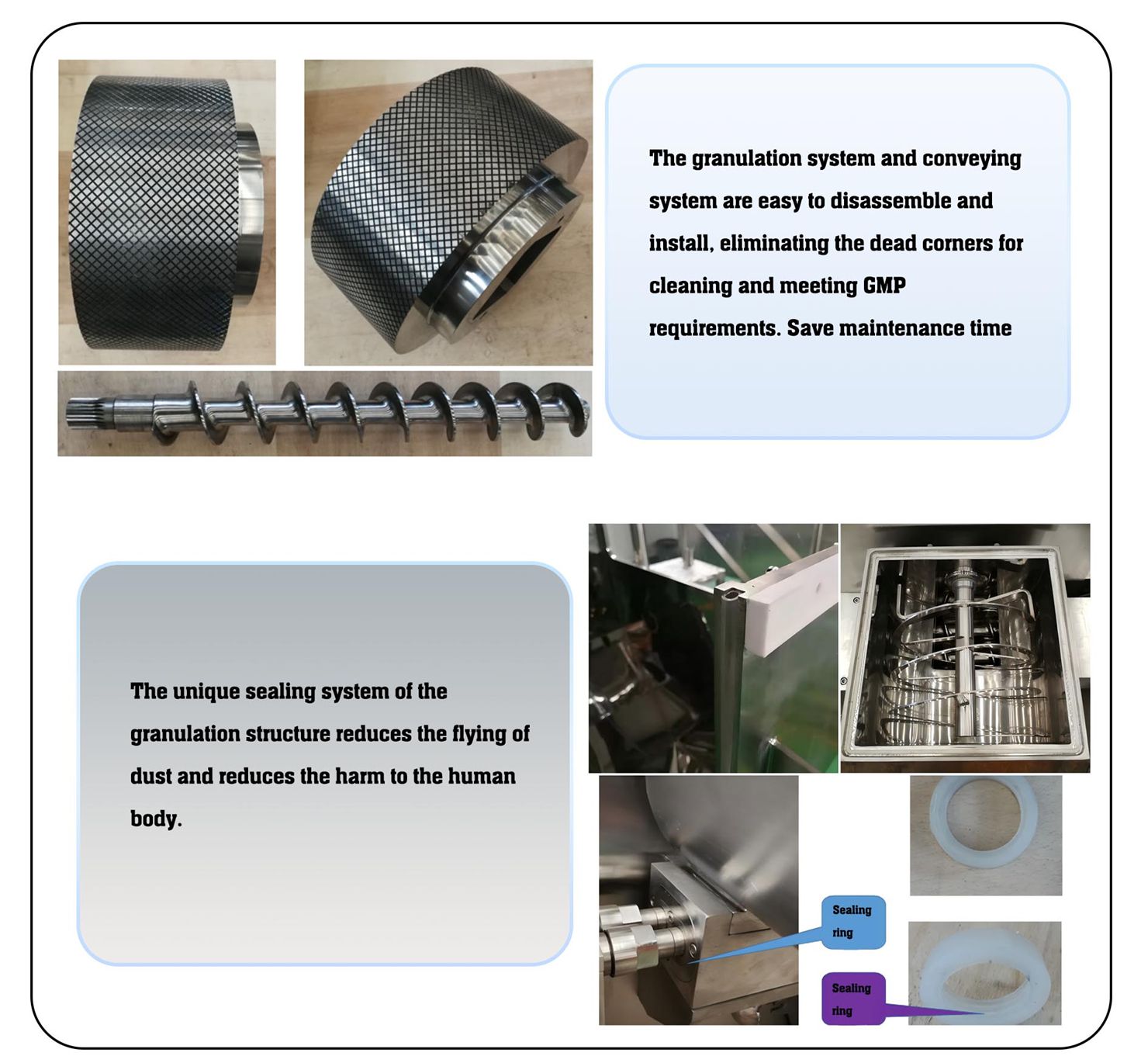

8. The equipment has a simple structure and is easy to disassemble and clean;

9. Equipped with a vacuum device to make the tableting more dense and the granulation rate high;

10. There are three types of pressing wheels with mesh, straight and smooth patterns to match materials with different characteristics;

11. The control system has a built-in memory that can store tens of millions of sets of production data;

12. The equipment adopts PLC control, the human-machine interface is beautiful and simple, and the operation is convenient and easy to learn.

13.GMP compliant - meets pharmaceutical industry standards.

Machine details:

Technique Parameter:

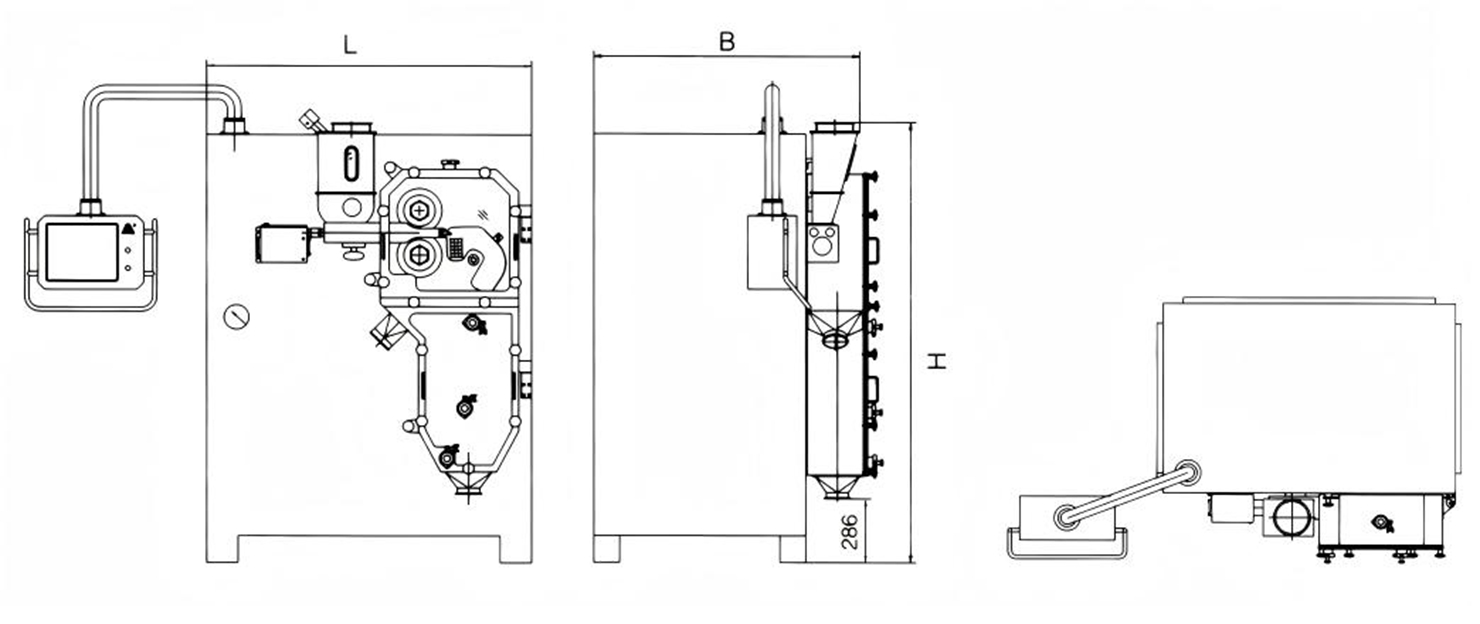

Model | Main structural dimensions(L*W*H) | Particle fineness | Production capacity | Pressure roller | Motor power | Weight |

LG-20 | 1100*1000*1600 | 15-60 | 20 | 4 | 8.75 | 0.7 |

LG-40 | 1100*1000*1600 | 15-60 | 40 | 4 | 11.5 | 0.7 |

LG-70 | 1200*1000*1880 | 15-60 | 70 | 4 | 13.5 | 0.9 |

LG-100 | 1445*1400*1982 | 15-60 | 100 | 5 | 18.5 | 1.1 |

LG-150 | 1445*1400*1982 | 15-60 | 150 | 5 | 18.5 | 1.25 |

LG-200 | 1600*1530*2100 | 15-60 | 200 | 5 | 21.6 | 2 |

LG-300 | 1600*1530*2100 | 15-60 | 300 | 6 | 23.7 | 2.7 |

LG-400 | 5100*2100*1800 | 15-60 | 400 | 6 | 28.6 | 3.2 |

LG-500 | 6300*3250*2200 | 15-60 | 500 | 6 | 32.6 | 4 |