Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DPH-260

Innov

Machine Introduction

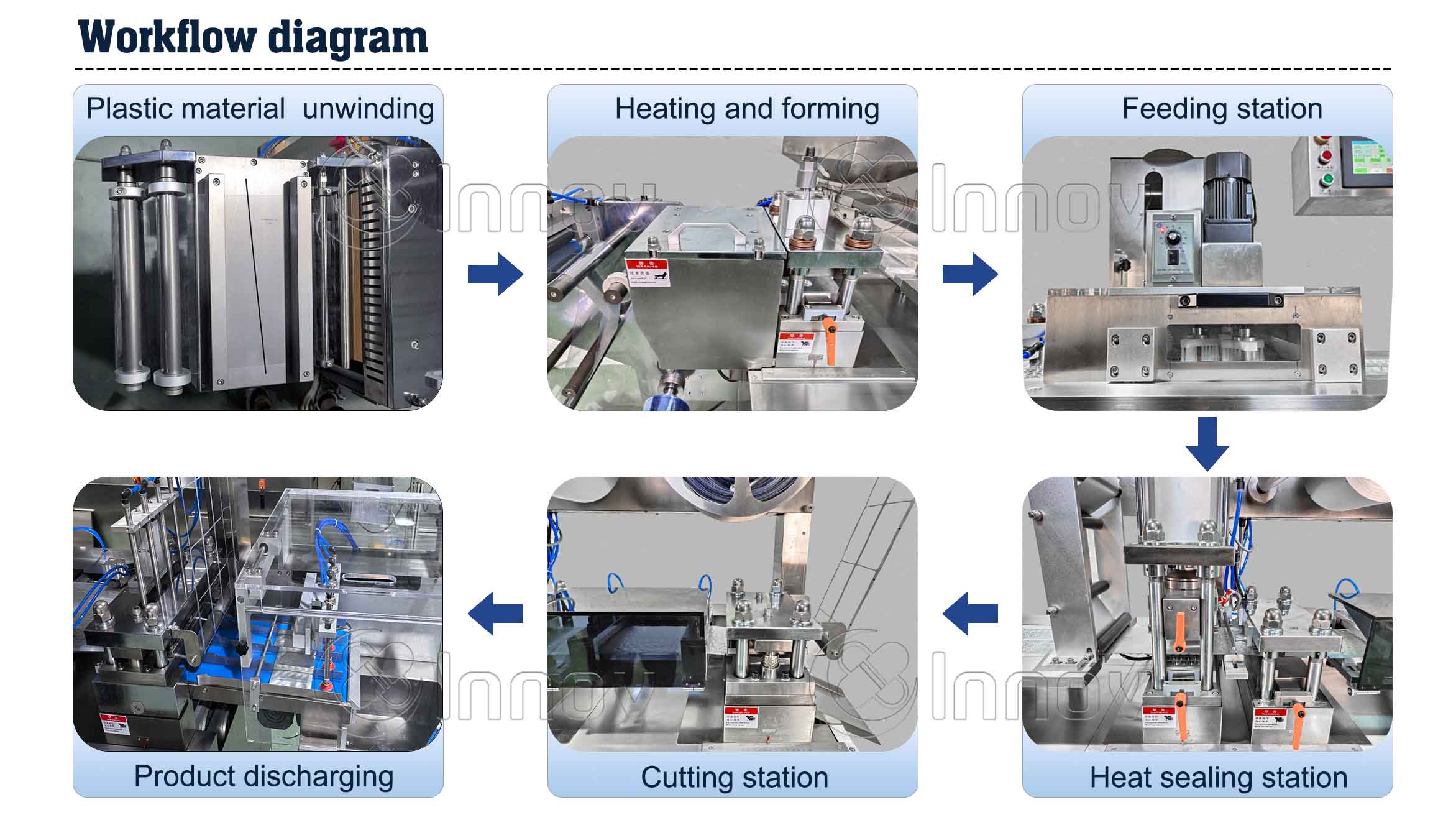

This machine uses positive pressure forming and roller heat sealing, it features crisp blister packs and flat plates. Its punching speed can reach up to 180 times per minute, which is 4-5 times higher than ordinary blister packaging machines. It combines the advantages of flatbed and roller blister packaging machines and is equipped with a special tablet feeder (an automatic capsule turning machine can also be added). It features high punching frequency, low energy consumption, accurate and stable operation, convenient mold replacement, and high yield. In particular, it can adapt to various irregularly shaped medicines and plates, greatly improving production efficiency.

Sample Photo

Working Process

Technical Parameters

Name | Specification |

Punch frequency | 60~150 pcs/min |

Production capacity | 10800~18000 plates/hour(Alu-PVC) |

Max. forming area | 260×240mm |

Max. forming depth | Standard: 12mm Customized: 26mm(Aluminum foil-plastic),with additional cost 18mm(Aluminum-Aluminum),with additional cost |

Stroke range | Standard: 40~240mm |

Servo motor power | 7.5KW |

PVC and PTP width and thickness | PVC: 260×0.25~0.45mm PTP: 260×0.02~0.03mm Duralumin:260 |

Power supply | 380V 50HZ, 18.5KW |

Air consumption | ≥0.5m3/min |

Water required for cooling | Tap water or circulating water consumption 60L/H |

Overall dimension | 5400×1380×2100mm |

Overall weight | 3500kg |