Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

ZP-13B/15B/17B/19B/21B

Innov

Machine Introduction

During operation, the depth of the filler and the thickness of the tablets can be adjusted. The tableting pressure is set by a hydraulic drive system, and a pressure gauge on the system displays the pressure value. The system has a built-in overload protection device to prevent damage to the punch and equipment in case of overload; the machine will automatically stop in case of overload.

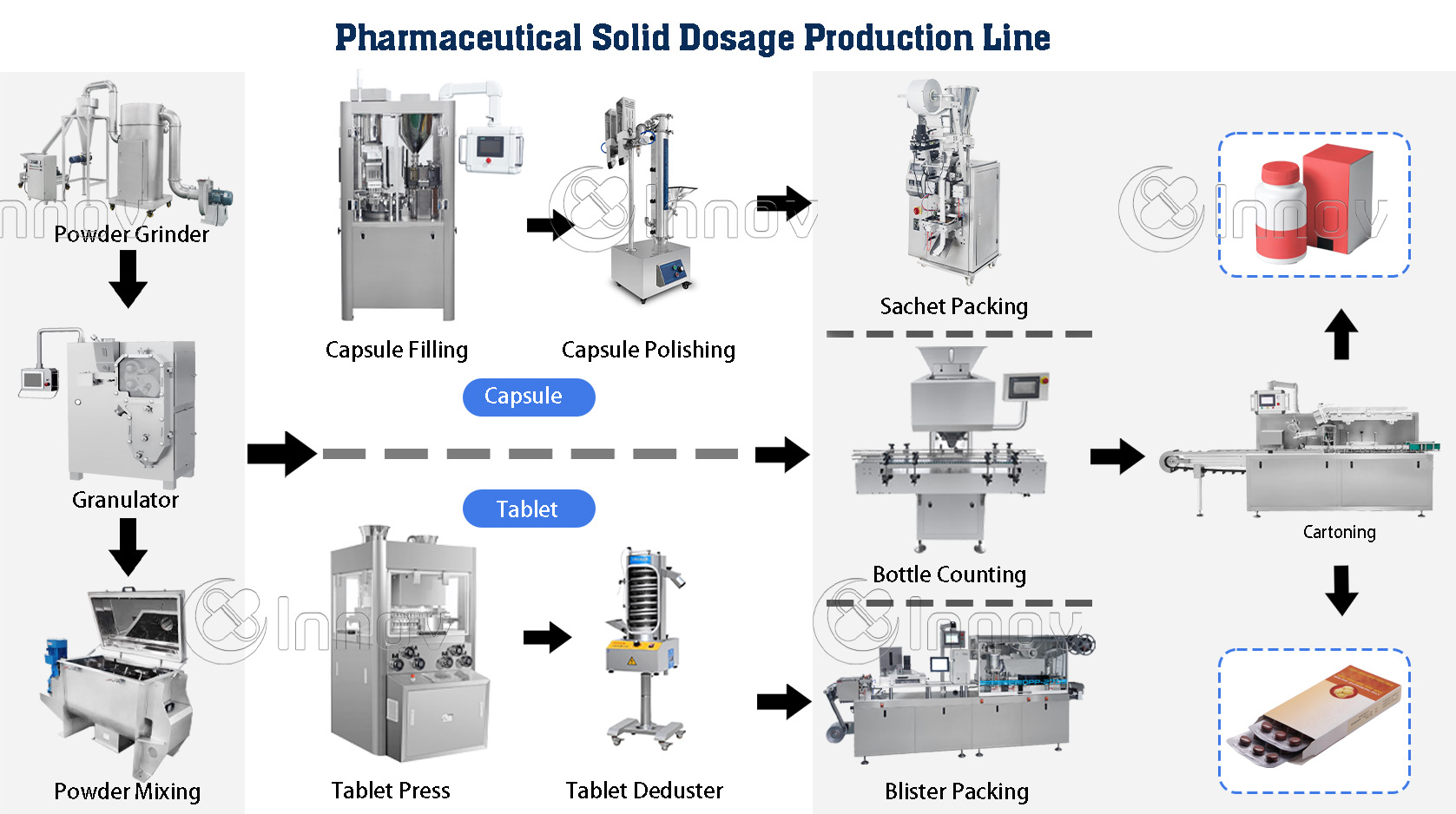

We also have continuous rotary multi-punch tablet presses models to help you increase production output or for these special tablet types, and also can be worked with tablet coating machines, blister packing machines, semi-automatic counting machine or fully automatic bottle counting production line for pharmaceutical products.

Machine Details

Technical Parameter

Dies (sets) | 13 | 15 | 17 | 19 | 21 |

Max. Pressure (kn) | 150 | 150 | 120 | 120 | 80 |

Max. dia. of tablet (mm) | 50 | 45 | 40 | 30 | 30 |

Max. Depth of fill (mm) | 18-25 | 18-25 | 18-25 | 18-25 | 18 |

Max. Thickness of largest table (mm) | 8-15 | 8-15 | 8-15 | 8-15 | 9 |

Turret speed (r/min) | 10-25 | 10-25 | 10-25 | 10-25 | 10-36 |

Length of up and down punch pole (mm) | 36 | 36 | 36 | 36 | 36 |

Length of up punch pole (mm) | 175 | 175 | 175 | 175 | 175 |

Length of down punch pole (mm) | 180 | 180 | 180 | 180 | 185 |

Diameter of middle mould (mm) | 40 | 40 | 40 | 40 | 40 |

Production capacity (pcs/h) | 7800-19500 | 9000-23000 | 10200-25500 | 11400-28500 | 45000 |

Motor power (kw) | 7.5 6Pole | 7.5 6Pole | 7.5 6Pole | 7.5 6Pole | 3 |

Overall size (mm) | 900*800*1640 | ||||

Weight (kg) | 1500 | 1500 | 1500 | 1500 | 1500 |

Moulds Display