Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

Views: 421 Author: Site Editor Publish Time: 2026-02-01 Origin: Site

Automatic capsule filling machines are classified into intermittent rotary type (represented by BOSCH's GKF model) and continuous rotary type (represented by MG2's MG series) based on their worktable motion form. Currently, the intermittent type automatic capsule filling machine is widely used in China, so the following will introduce the structure and working principle of capsule filling machines based on this type.

The disordered hollow capsules from the storage hopper pass through the orientation arrangement device, making all capsules stand with the capsule cap facing up, and then fall into the capsule plate holes on the main work.

Orientation Principle:1. The pushing force of the pusher acts on the capsule body; 2. The width of the slide slot is smaller than the outer diameter of the capsule cap but larger than the outer diameter of the capsule body, so the slide slot only has a clamping effect on the capsule cap without contacting the capsule body.

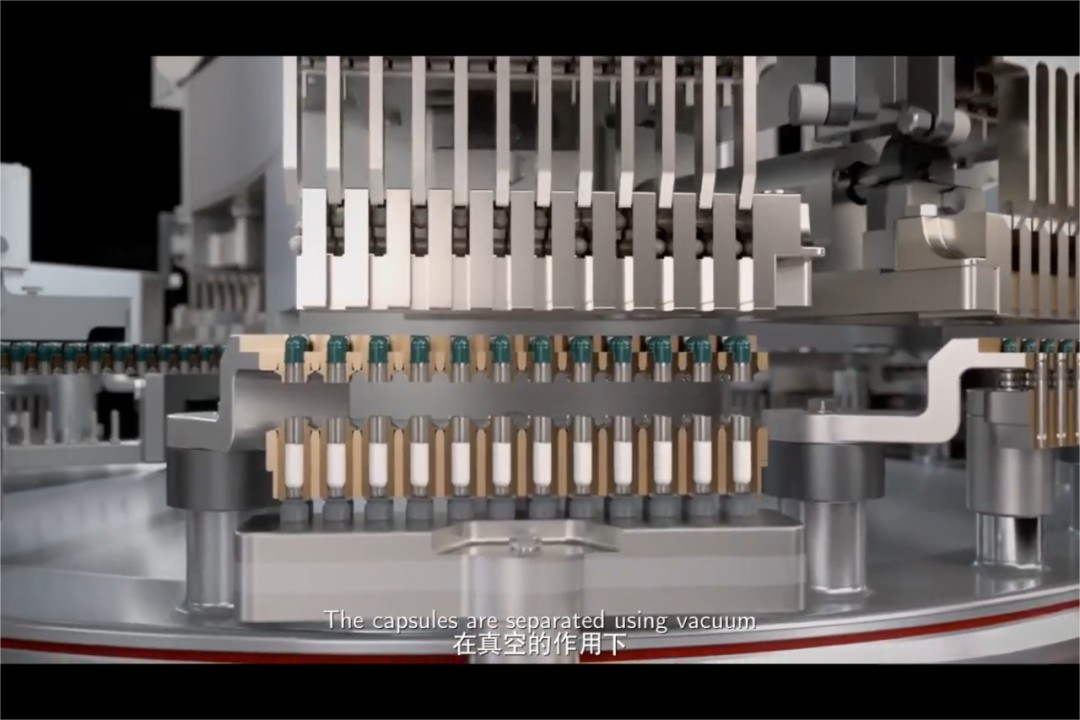

Using the slight differences in hole diameters of the capsule plate and vacuum suction, the capsule cap remains on the upper capsule plate while the capsule body falls into the lower capsule plate hole.

The upper capsule plate moves away along with the capsule cap, positioning the upper opening of the capsule body below the metering filling device for convenient drug filling.

Drugs are filled into the capsule body of the lower capsule plate using template metering or tube metering methods.

Unseparated empty capsules are rejected from the upper capsule plate to prevent mixing with filled capsules.

The upper and lower capsule plate holes are aligned axially, and the capsule cap is closed with the filled capsule body using external pressure.

The closed capsules are pushed out from the upper and lower capsule plate holes. A dust removal system clears powder and broken capsule shells from the upper and lower capsule plate holes.