Tel: +86-18874804206 E-mail: sales@innovequipment.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- Home

- Products

- About Us

- News

- Support

- Application

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

HED-XG

Innov

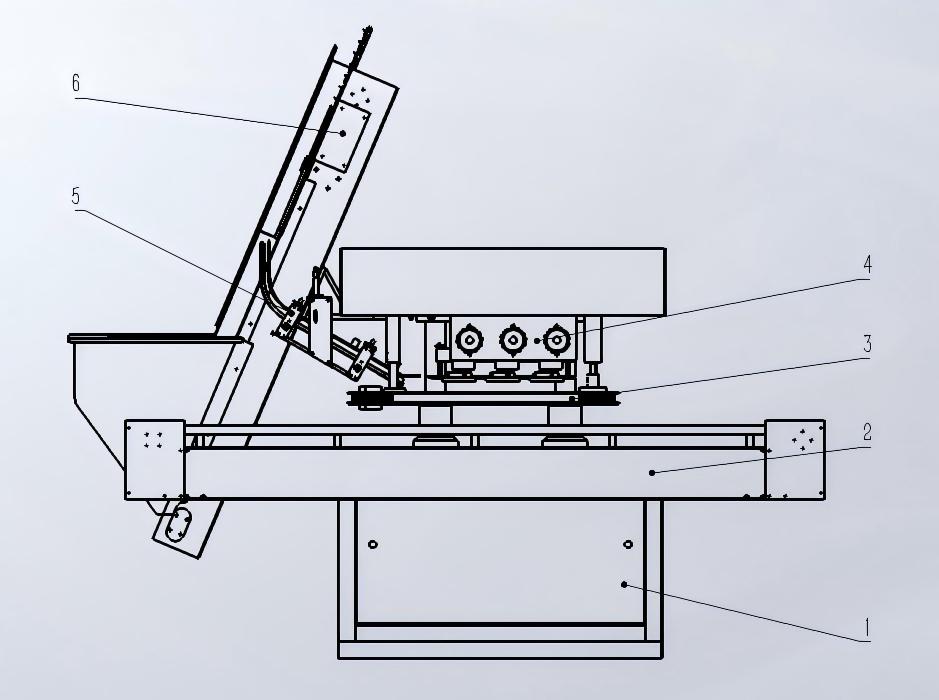

1. Rack parts | 2. Conveying parts |

3. Bottle clamping parts | 4. Capping parts |

5. Cap dropping parts | 6. Lifting capping mechanism |

(1) The hoist feeds caps, and the cap feeding speed is stable.

(2) Reliable operation: stable operation and low noise;

(3) Anti-high dust: The unique anti-high dust photoelectric sensor is adopted.

(4) Function matching: automatic detection of whether there is aluminum foil in the bottle cap with photoelectric sensor for lack of bottle or blocked bottle

(5) Simple operation: various operating specifications can be set as required

(6) Convenient maintenance: the operator only needs simple training to operate, and the disassembly, cleaning and replacement of parts are simple and convenient, and no tools are required;

(7) Sealed and dustproof: It is equipped with a plexiglass cover to reduce dust pollution.

(1) Applicable bottle range: Φ23-Φ120/45-150.

(2) Suitable for bottled containers: plastic bottles with an inner diameter of Ф 20-80, a diameter of Ф 20-80, and a bottle height of 30-130.

(3) Production speed: 25-80 bottles/min (related to material variety, size, bottle specifications, and bottled volume)

(4) Capping coverage rage: ≥99.8%

(5) Power supply and power: 110v 50hz

(7) Weight: 340Kg

(8) Dimensions: 2440*1220*2050 (㎜)